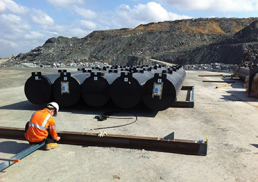

Clyde Creek SPS Mechanical Installation

Project Overview

Client : Fulton Hogan – Deplant – Beca

Date : 8 January 2017

Info : South East Water Authority

Scope:

Mechanical installation of the all mechanical components, inlet and outlet pipework, turret top, ventilation stack and valve pit lids.

Including the following components:

Flygt NP3231.170, 125kW motor waste water submersible pumps – 2 units

Flygt NP3231.170, 125kW motor waste water submersible pumps – 2 units Pump pedestals and upper guiderail brackets to suit.

Pump pedestals and upper guiderail brackets to suit. Flygt 4620.410, 1.5kW motor submersible mixers – 2 units

Flygt 4620.410, 1.5kW motor submersible mixers – 2 units Mixer pedestals and upper guiderail brackets to suit.

Mixer pedestals and upper guiderail brackets to suit.

DIEL Discharge pipework consisting of :

DN300 Ductile Iron Ball Check Valve – 2 units

DN300 Ductile Iron Ball Check Valve – 2 units DN300 Ductile Iron Resilient Seated Gate Valve – 2 units

DN300 Ductile Iron Resilient Seated Gate Valve – 2 units DN150 Resilient Seate Gate Valve

DN150 Resilient Seate Gate Valve DN150 DIEL Tee with valve controlled 4″ Female Camlock and Male Dust Cap and riser for connection.

DN150 DIEL Tee with valve controlled 4″ Female Camlock and Male Dust Cap and riser for connection. 450x450mm AWMA Penstock Valve

450x450mm AWMA Penstock Valve Wet Well Washer – 2 unit

Wet Well Washer – 2 unit DN500 SS316 Lugged Resilient Seated Knife Gate Valve – 2 units

DN500 SS316 Lugged Resilient Seated Knife Gate Valve – 2 units DN500 SS316 Dropper pipes with DN500 T Piece c/w sealed top and DN150 Screw Cap

DN500 SS316 Dropper pipes with DN500 T Piece c/w sealed top and DN150 Screw Cap SS316 8 meter Ladders complete with staunchions – 2 units (Wet well)

SS316 8 meter Ladders complete with staunchions – 2 units (Wet well) SS316 2 meter Ladders complete with staunchions – 2 units (Valve Pit)

SS316 2 meter Ladders complete with staunchions – 2 units (Valve Pit) 4500x1520mm Wet Well Turret Top

4500x1520mm Wet Well Turret Top 6 meter Vent Stack

6 meter Vent Stack

3725 x 1850mm McBern’s Class A 180 degree opening Aluminium Cover

Concrete benching and pedestal landings at wet well base.